- We focus on manufacturing beauty machines

- Tell:+8615920595182

- Whatsapp:+8615920595182

- beauty1@bestauro.com

AU-23F monopolar RF skin rejuvenation face lifting beauty equipment temperature control

For the Monopolar RF skin rejuvenation face lifting beauty equipment is the very popular machine, it is very Mature in the market. Our factory upgrade it every year.

On our new version Monopolar RF machine, we have some feedback from our distributor, His feedback as below:

“Dear Justin,

I am looking forward to get some good news from you. Also, if it helps I can send you some photos that we made from a good (strong) AU-23F PCB.

I myself (even though no engineer) have compared the photos with one of the new “bad” (or weak) boards, and hardly

could find any difference. Both use the some heat controller chip and the electronic components seem to be quite similar. There are only small differences which I think

may not be the cause for the weakness of the new boards (but again, I am no engineer). Both boards use the same revision 2015-11-xx. Don’t know what is causing the new boards to be so much weaker.

And I fear you may not know too. Nevertheless I hope you’re making some progress with your engineers in regards of finding the root cause. Waiting for your news”

From this email, we found that some customers like the strong monoplar RF machine, it will have better effect on face lifting.

After some study on this machine, we found that reason. Our new circuit board have the overheat control on the circuit board, it can better protection the machine.

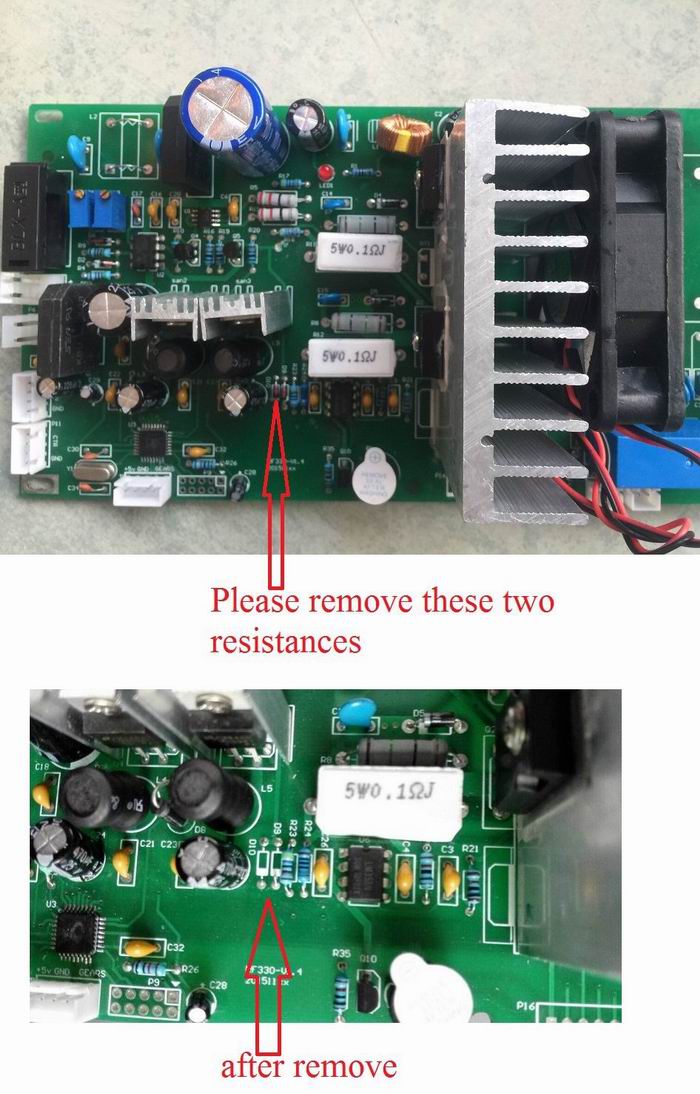

For the customer requirement, we just remove two elements on the circuit board, the problem solve as the photo showing.

We received the distributor reply again:

Dear Justin,

We tested two different setups yesterday, with PCB boards modified accordingly to your instructions.

Board 1: both diodes removed as suggested by you on skype yesterday

Board 2: Controller IC removed (we did that last week already) plus both diodes removed – again following your recommendation yesterday.

Result board 1 (both diodes D9+D10 removed):

We did a stress test with the PCB board where we have removed the diodes only accordingly to your instructions from Wednesday. Interestingly this machine gets fairly warm with air temperature up to 45-50°C coming out of the ventilation hole after 30 minutes running on power level 10. Nevertheless, the controller IC seemed to regulate power in a sense that the heat on the IRFP 450 components didn’t rise above 85°C. It actually did once get to almost 85°C but then dropped down to about 70°C and stayed there oscillation between 65-75°C. This machine passed our stress test.*

Result board 2 (controller IC U6 and both diodes D9+D10 removed):

We have tested the 2nd PCB where we have removed the controller IC last week. We have removed the two diodes as well, accordingly to what you have suggested yesterday in our skype discussion.

The machine worked well the first 4 minutes and then out of the sudden shut down (died). We tested the machine first on power level 1 for about 1 minute. Then for another 2 minutes on level 5 and finally 1 minute on level 10 (max). After about 1 minute on level 10 AU-23F shut down. This machine obviously failed our stress test. The ventilation air was still fairly cold when the PCB board died. We didn’t have the time to take a proper heat measurement as we were a bit taken by surprise on how quickly the board said “goodbye”.

Conclusions (preliminary):

1) removing the 2 diodes D9 and D10 seems to be a viable solution. The machine operates in terms of applicator heat in an area which we would describe as optimal. I hope long-term results will confirm our impression.

2) removing the 2 diodes and removing the controller IC doesn’t seem to be a feasible solution as this setup doesn’t seem to be capable of dealing with high loads.

*The temperature measurements are only approximative as we use a small portable IR pen-device only for ad-hoc measuring. We took our measurement from the back of the machine where the ventilation hole is and from the IRFP 450 components inside the case.

Just wanted to share our findings with you. Hope it will be useful.

Please Email us for more information or Add whatsapp: +8615920595182